Electronic connectors are the unsung heroes of modern technology, facilitating crucial connections in everything from smartphones to industrial machinery. As devices become increasingly complex, the reliability of these connectors becomes paramount. Proper maintenance and troubleshooting of electronic connectors are essential skills for anyone working with electrical equipment. This knowledge not only extends the life of your devices but also ensures optimal performance and prevents costly downtime.

Types of electronic connectors in modern equipment

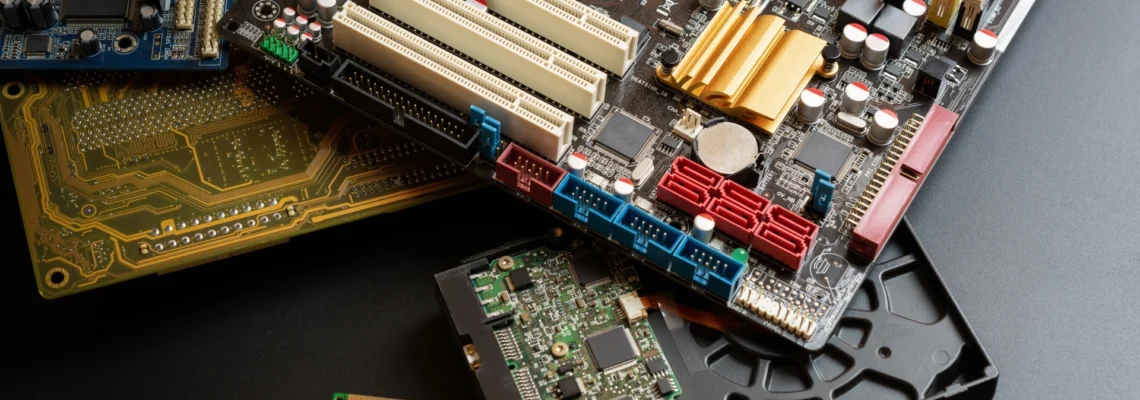

Understanding the various types of electronic connectors is crucial for effective maintenance and troubleshooting. Modern equipment utilizes a wide array of connector types, each designed for specific applications and environments. From simple pin and socket connectors to complex fiber optic interfaces, the diversity of connectors reflects the evolving needs of electronic systems.

Some common types of electronic connectors include:

- Pin and socket connectors

- Coaxial connectors

- Fiber optic connectors

- USB connectors

- HDMI connectors

Each type of connector has its unique characteristics and potential vulnerabilities. For instance, pin and socket connectors are susceptible to bent pins, while fiber optic connectors are particularly sensitive to contamination. Understanding these nuances is crucial for effective maintenance.

For a comprehensive guide on electronic connector types, features, and applications, refer to the resources available at icape-group.com. This knowledge will serve as a foundation for your maintenance and troubleshooting efforts.

Essential tools for connector maintenance

Proper maintenance of electronic connectors requires a set of specialized tools. These tools not only facilitate cleaning and inspection but also help in diagnosing and resolving issues. Investing in quality tools can make a significant difference in the effectiveness of your maintenance routine.

Multimeters and continuity testers

Multimeters are indispensable for testing electrical connections and diagnosing issues. They allow you to measure voltage, current, and resistance, providing crucial data for troubleshooting. Continuity testers, often integrated into multimeters, are essential for checking the integrity of connections and identifying breaks in circuits.

When selecting a multimeter, consider features such as:

- Auto-ranging capability

- True RMS measurements

- Capacitance and frequency measurement

- Diode and continuity test functions

Contact cleaning solutions and brushes

Specialized contact cleaning solutions are formulated to remove oxidation, dirt, and other contaminants without damaging the connector surfaces. These solutions are typically non-conductive and leave no residue. Pair these with soft-bristled brushes designed for electronic components to effectively clean connector surfaces without causing damage.

Always use cleaning solutions specifically designed for electronic connectors to avoid potential damage or conductivity issues.

Precision screwdrivers and tweezers

Many electronic connectors are secured with small screws or require precise manipulation during maintenance. A set of precision screwdrivers and tweezers is essential for working with these delicate components. Look for tools made from anti-static materials to prevent electrostatic discharge (ESD) damage.

Esd-safe work mats and wrist straps

Electrostatic discharge can cause severe damage to sensitive electronic components. An ESD-safe work mat and wrist strap are crucial for creating a safe work environment. These tools help dissipate static charges, protecting your equipment during maintenance procedures.

Preventive maintenance techniques for connectors

Preventive maintenance is key to extending the life of electronic connectors and ensuring reliable performance. By implementing a regular maintenance routine, you can identify and address potential issues before they lead to equipment failure.

Proper cleaning methods for different connector types

Different connector types require specific cleaning approaches. For example, optical connectors demand meticulous cleaning to maintain signal integrity, while power connectors may require more robust cleaning methods to remove oxidation and debris.

For optical connectors:

- Use specialized lint-free wipes

- Apply a small amount of isopropyl alcohol

- Gently clean the connector face

- Dry with clean, compressed air

For power connectors, a contact cleaner spray followed by gentle brushing is often effective. Always refer to manufacturer guidelines for specific cleaning recommendations.

Applying contact enhancers and lubricants

Contact enhancers and lubricants can significantly improve connector performance and longevity. These products help reduce friction, prevent oxidation, and enhance conductivity. However, it’s crucial to use products specifically designed for electronic connectors and apply them sparingly.

Over-application of lubricants can attract dust and debris, potentially causing more harm than good.

Inspection protocols for early wear detection

Regular visual inspections can help identify early signs of wear or damage. Develop a systematic inspection protocol that includes:

- Checking for physical damage or deformation

- Looking for signs of corrosion or oxidation

- Assessing the condition of protective coatings

- Examining for loose or misaligned pins

Use magnifying tools or a digital microscope for detailed inspections of smaller connectors. Document your findings to track changes over time and identify recurring issues.

Environmental control strategies

The environment in which connectors operate significantly impacts their lifespan and performance. Implementing environmental control strategies can mitigate many common issues:

| Environmental Factor | Control Strategy |

|---|---|

| Humidity | Use desiccants or dehumidifiers |

| Temperature | Implement proper ventilation and cooling systems |

| Dust and Debris | Install filters and maintain a clean environment |

| Vibration | Use shock-absorbing mounts and secure connections |

Troubleshooting common connector issues

Even with diligent maintenance, connector issues can arise. Effective troubleshooting requires a systematic approach and a deep understanding of common problems.

Diagnosing intermittent connections

Intermittent connections are often the most challenging issues to diagnose. They can be caused by loose contacts, thermal expansion, or microscopic cracks. To troubleshoot intermittent connections:

- Perform visual inspections under magnification

- Use a continuity tester to check for breaks in the connection

- Apply gentle pressure or movement to identify loose connections

- Test under various temperature conditions to identify thermal issues

Patience and methodical testing are key when dealing with intermittent connection problems.

Identifying and replacing corroded contacts

Corrosion can significantly impair connector performance. Identifying and addressing corrosion early is crucial. Look for discoloration, pitting, or a buildup of greenish or white substances on connector surfaces. In many cases, corroded contacts will need to be replaced to ensure reliable connections.

Resolving pin misalignment problems

Pin misalignment can occur due to physical stress or improper insertion. This issue can lead to poor connections or even damage to the connector. To resolve pin misalignment:

- Carefully inspect the connector under magnification

- Use precision tools to gently realign bent pins

- Consider replacing severely misaligned connectors

- Implement proper insertion techniques to prevent future misalignments

Addressing signal integrity issues

Signal integrity problems can manifest as data errors, reduced bandwidth, or complete signal loss. These issues often stem from impedance mismatches, crosstalk, or electromagnetic interference. Troubleshooting signal integrity requires specialized equipment such as oscilloscopes and network analyzers.

Advanced connector repair techniques

Sometimes, standard maintenance and troubleshooting techniques are insufficient, and more advanced repair methods are necessary. Advanced repair techniques require specialized skills and tools but can often salvage connectors that would otherwise need replacement.

One advanced technique is pin replacement, which involves carefully removing damaged pins and inserting new ones. This process requires steady hands, specialized extraction tools, and often, a microscope for precision work. Another advanced technique is connector re-pinning, where the entire pin layout of a connector is modified to meet new specifications or repair extensive damage.

Advanced repair techniques should only be attempted by trained professionals with the proper equipment. Improper repairs can lead to further damage or create safety hazards.

For high-frequency connectors, advanced repair might involve re-plating contact surfaces to restore optimal conductivity. This process typically requires specialized equipment and is often performed by dedicated repair services.

Upgrading and replacing obsolete connectors

As technology evolves, certain connector types may become obsolete or no longer meet the performance requirements of modern systems. Upgrading connectors can improve system performance, reliability, and compatibility with new equipment.

When considering connector upgrades:

- Assess the current and future needs of your system

- Research compatible modern connector types

- Consider the impact on existing equipment and cabling

- Evaluate the cost and potential downtime for upgrades

Replacing obsolete connectors often involves more than just swapping out the connector itself. You may need to modify PCB layouts, update cabling, or even redesign portions of your system to accommodate new connector types.

When upgrading, consider factors such as:

| Factor | Consideration |

|---|---|

| Signal Integrity | Higher bandwidth and lower crosstalk |

| Power Handling | Increased current capacity and efficiency |

| Environmental Resistance | Better sealing and corrosion resistance |

| Size and Weight | Compact designs for space-constrained applications |

In some cases, adapter solutions can bridge the gap between old and new connector types, allowing for gradual upgrades without complete system overhauls. However, these adapters may introduce their own set of challenges, such as signal degradation or mechanical stress points.

As you navigate the complex world of electronic connectors, remember that proper maintenance, effective troubleshooting, and strategic upgrades are key to ensuring the reliability and longevity of your electronic systems. By applying the techniques and considerations outlined in this guide, you can maintain optimal performance and minimize downtime in your equipment.